„We just save a lot of time.“

Fritz Hachmöller is a farmer, 28 years old and runs a modern pig fattening farm in Cappeln-Sevelten with his father Berthold Hachmöller (58). In this interview, he talks about the challenges of the current requirements of the livestock ordinance, about the switch to the tieraktiv system from Witte and about the advantages of automating the feeding of roughage and manipulable materials in the pig houses.

You run a farm in the field of sow keeping and pig fattening. How big is your farm?

Fritz Hachmöller: We keep about 550 sows in a closed system and about 3000 piglets in our rearing houses. There are currently around 6000 animals in the fattening pens. We produce an average of 18,000 to 19,000 fattening pigs per year. In addition, we farm about 70 hectares of grain and maize, which we take to the nearby mill. For about five years we have been contract fatteners for Westfleisch, the third largest meat processing company in Germany.

This year you have built an additional farrowing house. The Witte tieraktiv system is used in it. How did you decide to use the system?

Fritz Hachmöller: On the one hand, to comply with the requirements of the current Animal Welfare Ordinance. On the other hand, the automation of roughage feeding and the resulting time savings was a decisive factor for us. In addition to the required increase in the size of the stalls, the provision of roughage and manipulable material is also prescribed. Until now, our employees have spent about two to three hours every morning feeding straw or hull bran manually, bay by bay. An extremely time-consuming process. With the new tieraktiv system it is much easier: We save a lot of working time and can focus entirely on the animals. And especially during local inspections, we can be sure that everything always fits and that the specifications are 100% fulfilled.

How does the distribution of the feed work?

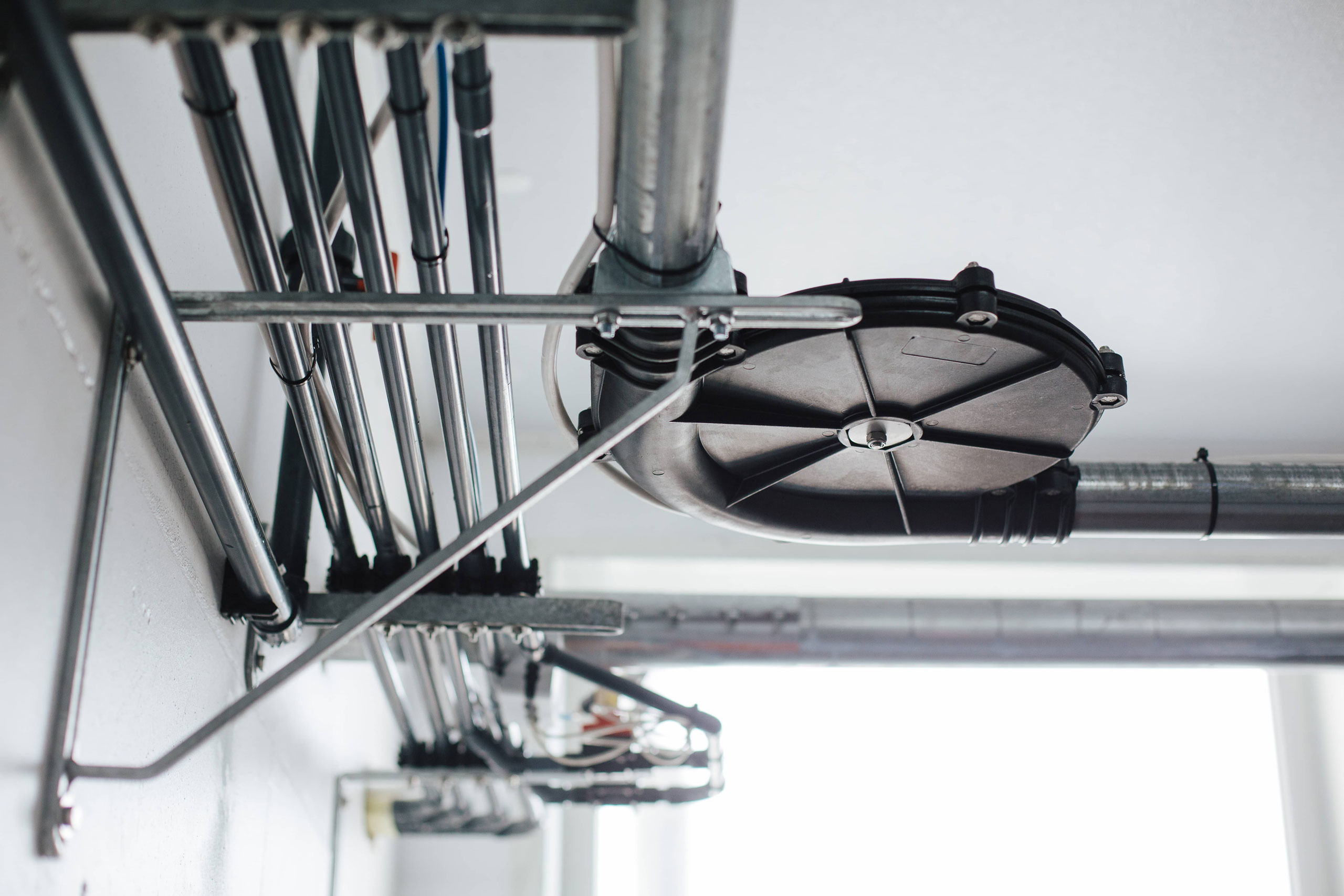

Fritz Hachmöller: We fill the feed hopper twice a week, the rest is fully automatic. In the newly built stalls we have a total of three running chains that are switched separately from each other. These are triggered by a timer set by me and the feed material is distributed several times a day through 80 mm pipes into the pens. The return flow of the straw is transported back into the hopper by means of the chain conveyor through the closed circuit. This way we do not waste any material. Both sows and piglets rummage through and eat the straw. It goes down well!

What manipulable material do you use with the Witte tieraktiv system?

Fritz Hachmöller: We have started with chopped straw. In addition, we will soon apply maize silage. This is particularly good for the sows’ gastrointestinal tract and ensures good digestion. This improves the sows’ performance. The material also brings variety into the barn – which in turn reduces the stress factor of our animals. In future, we will produce the straw chips in close cooperation with a contractor from the region. This is cost-effective – and we know exactly where it comes from.

What made you decide on tieraktiv from Witte?

Fritz Hachmöller: Our attention was drawn to it by our Witte distributor, who has been with us for a long time. Our conventional feed chains for feeding also come from Witte. We are very satisfied with the quality of the products. They are low-maintenance, extremely durable and easy to clean. In short: Witte’s quality simply speaks for itself.

Thank you very much for the interview!